Twinny S

Lightweight, versatile, and engineered for perfection, the Leister Twinny S delivers flawless welds for thin membranes and liners in demanding construction environments.

- Ideal for overhead welding in tunnel construction and underground projects

- Lightweight design reduces operator fatigue during extended use

- Variable temperature and drive settings for precise control

- Comes with a durable tool case for easy transport and storage

- Optimized for welding thin membranes and liners with consistent results

Sunday - Thursday

08:00 AM - 06:00 PM

Disclaimer: Please note that images or illustrations may differ from the actual products due to presentation reasons and are therefore non-binding. Technical changes and errors are excepted. For the most accurate information, contact our customer service team.

Introducing the Leister Twinny S: Your Ultimate Solution for Precision Overhead Plastic Welding

When it comes to tunnel construction and underground projects in Saudi Arabia, precision and reliability are non-negotiable. The Leister Twinny S is engineered to deliver just that—consistent, high-quality welds for thin membranes and liners, even in challenging overhead applications.

Why Choose the Leister Twinny S?

Plastic welding in demanding environments like Riyadh and Jeddah requires tools that combine innovation with ease of use. With its lightweight design and advanced features, the Twinny S ensures seamless performance where you need it most.

- Ideal for Various Membranes in Underground Projects: Whether you’re working on tunnel waterproofing or lining systems, the Twinny S handles a wide range of membranes with ease. Its versatility makes it indispensable for contractors tackling complex underground projects across the Kingdom of Saudi Arabia.

- Optimized for Overhead Welding: Designed specifically for overhead applications, this machine reduces operator fatigue while maintaining exceptional welding quality. This feature is particularly valuable in tunnel construction, where overhead work is often unavoidable.

- Temperature and Drive Variably Adjustable: Achieve precise control over your welding process with adjustable temperature and drive settings. These customizable options ensure optimal results for different materials and thicknesses, enhancing both efficiency and durability of the welds.

- Durable Tool Case Included: Transporting and storing your equipment safely is crucial, especially in rugged construction environments. The Twinny S comes with a robust tool case, protecting your investment and keeping everything organized for easy access on-site.

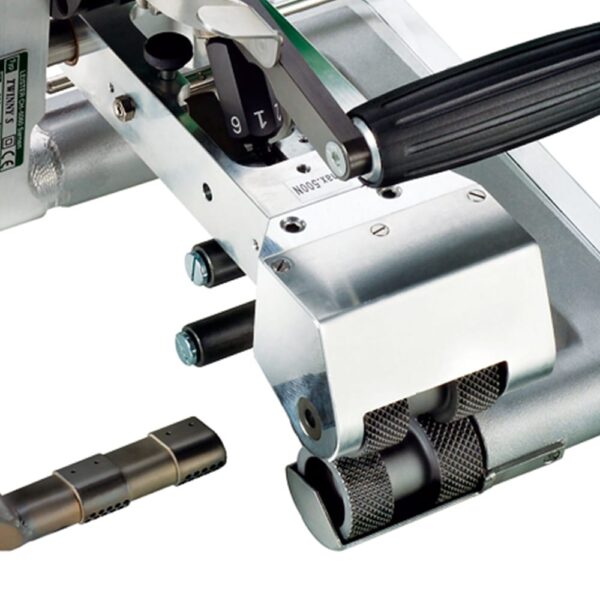

- Lightweight Design with Combi Wedge: Weighing in as a lightweight champion, the Twinny S reduces strain during prolonged use. Paired with its combi wedge, it simplifies welding thin membranes and liners, making it perfect for delicate yet critical applications.

Use Cases Where the Twinny S Excels

The Leister Twinny S shines in scenarios requiring meticulous plastic welding in tough conditions:

- Tunnel Construction: From Riyadh’s metro projects to Jeddah’s infrastructure upgrades, the Twinny S ensures leak-proof seals for tunnels and underground structures.

- Waterproofing Applications: Ideal for creating impermeable barriers in basements, reservoirs, and other subterranean spaces.

- Civil Engineering Projects: Perfect for welding geomembranes and liners in environmental containment systems.

- Roofing Solutions: Efficiently welds roofing membranes, ensuring long-lasting weather resistance for industrial and commercial buildings.

For construction professionals in Saudi Arabia seeking a dependable partner for their plastic welding needs, the Leister Twinny S stands out as a top choice. Backed by decades of expertise and trusted globally, this product exemplifies innovation, efficiency, and unmatched performance.

Support and Services for Twinny S from Global Source

At Global Source, we are committed to providing professionals in Riyadh and Jeddah with the highest quality products and services. Our partnership with Leister ensures that you receive cutting-edge welding solutions backed by over 70 years of expertise. Additionally, we offer:

- Comprehensive maintenance and repair services for Twinny S using original spare parts.

- Customized training sessions for Leister machines, available at our offices or your location.

- Local support and quick delivery options to keep your projects on track.

Get Your Twinny S Today!

Don’t miss out on the opportunity to elevate your welding capabilities. Stock is moving fast at our Riyadh and Jeddah locations! Contact Global Source today to order your Twinny S and experience the difference quality makes in your projects.

Sunday - Thursday

08:00 AM - 06:00 PM

Get personalized quote tailored to your needs on WhatsApp

Technical Data

-

Article119.024

-

Voltage230 V

-

Frequency50/60 Hz

-

Power2900 W

-

Temperature20 – 600 °C

-

Air Volume AdjustableYes

-

Speed0.8 – 4 m/min

-

Welding TechnologyCombi-Wedge

-

Combi-Wedge VersionShort

-

Hot Wedge Width50 mm

-

Hot Wedge MaterialStainless Steel

-

Max. Overlap125 mm

-

Max. Welding Pressure1000 N

-

Weld Seam Width2 x 15 mm / 2 x 0.59 in

-

Roll MaterialSteel Roller Sharp Diagonal

-

LQSNo

-

Brushless Blower MotorNo

-

DisplayNo

-

Length350 mm

-

Width390 mm

-

Height270 mm

-

Weight6.9 kg

-

Welding MaterialsCSPE; EPDM; FPO; HDPE; LDPE; LLDPE; PP; PVC; TPO

-

Weldable Material Thicknesses0.3 – 2 mm

-

PlugEU, 3 Poles, 16A

-

Power Cable Length3 m

-

ApprovalsCE; UKCA

-

Protection ClassII

-

Country of OriginSwitzerland

Applications

Nearly Limitless

Leister: A Legacy of Innovation in Plastic Welding Technology

Leister, a Swiss company with a rich history dating back to 1949, has established itself as a global market leader in plastic welding and process heat technologies. Renowned for their commitment to innovation and quality, Leister’s products have become the benchmark for industries requiring durable and efficient solutions. From roofing and civil engineering to tunneling and plastic fabrication, Leister’s tools are integral to various applications that demand precision and reliability.

Leister’s product portfolio is extensive, featuring hot-air hand tools, extruders, welding machines, and a wide array of accessories. These products cater to both DIY enthusiasts and industrial professionals, ensuring that every need is met with the highest standards of performance. Additionally, Leister Technologies AG extends its reach through the WELDY brand and private labeling options, further solidifying its presence in the global market.

With over 70 years of expertise, Leister continues to push the boundaries of technology, offering solutions that incorporate hot air, laser, and infrared technologies. Their unwavering dedication to research and development enables them to provide tailored solutions for diverse industrial requirements. This commitment to innovation, coupled with a global network of over 80 distributors, ensures that Leister remains at the forefront of the plastic welding and process heat industries.

Global Source is proud to partner with Leister, carefully curating their top-tier products to meet the specific needs of construction professionals in Saudi Arabia. By selecting only the best from Leister’s range, Global Source ensures that clients have access to reliable, efficient, and innovative solutions that enhance their projects and operations.

Construction Insights and Innovations

Stay Informed, Stay Ahead

Discover a wealth of knowledge designed for construction professionals navigating the dynamic landscape of Saudi Arabia. Our blog features articles that delve into the latest trends, tips, and innovations, covering everything from best practices in pipe welding to the advantages of Leister plastic welding solutions. Gain valuable insights that empower contractors, engineers, and builders to enhance their skills and optimize their projects. Join a community of forward-thinking professionals and elevate your expertise with every read.

Väli Manual Butt Fusion Welding Machines in Saudi Arabia – Precision HDPE Pipe Welding

Looking for HDPE pipe welding machines in Saudi Arabia? Explore the Väli VPWS Series for 20–200mm pipes. Available in Saudi Arabia with genuine spare parts, maintenance and expert technical support.

Understanding the Impact of New ASTM Standards on Geomembrane Welding in Saudi Arabia

Meet the latest ASTM standards in geomembrane welding with Leister equipment. Ensure quality and compliance with Global Source.

Unlocking Efficiency: The TRIAC AT Hot Air Hand Tool for Plastic Welding Professionals

Transform your construction projects with the TRIAC AT. Experience durability, safety, and energy efficiency with Global Source.

Transform Your Flooring Projects with the UNIFLOOR 500 from Leister

Maximize your flooring efficiency with the UNIFLOOR 500. Enjoy eco-friendly operation and easy transport for all your projects.

10 Compelling Reasons to Choose SHOXX Diamond Tools for Your Construction Projects in Saudi Arabia

Learn 10 compelling reasons to choose SHOXX diamond tools. Experience superior performance and safety for all your construction needs.

Achieve Seamless Perfection: The UNIDRIVE 505 Revolutionises Pool Membrane Welding

Upgrade your pool building process with the UNIDRIVE 505. Enjoy time savings and superior seam quality for every project.

Unleashing the Power of Precision: The Leister COMET 700 Hot Wedge Welding Machine

Invest in the COMET 700 for high-quality welds and efficient operations. Perfect for landfills, ponds, and aquaculture projects.

Mastering Tarpaulin Welding: Discover the UNIPLAN 500 from Leister

Explore the advantages of the UNIPLAN 500 for tarpaulin welding. Experience seamless operation and expert support from Global Source.