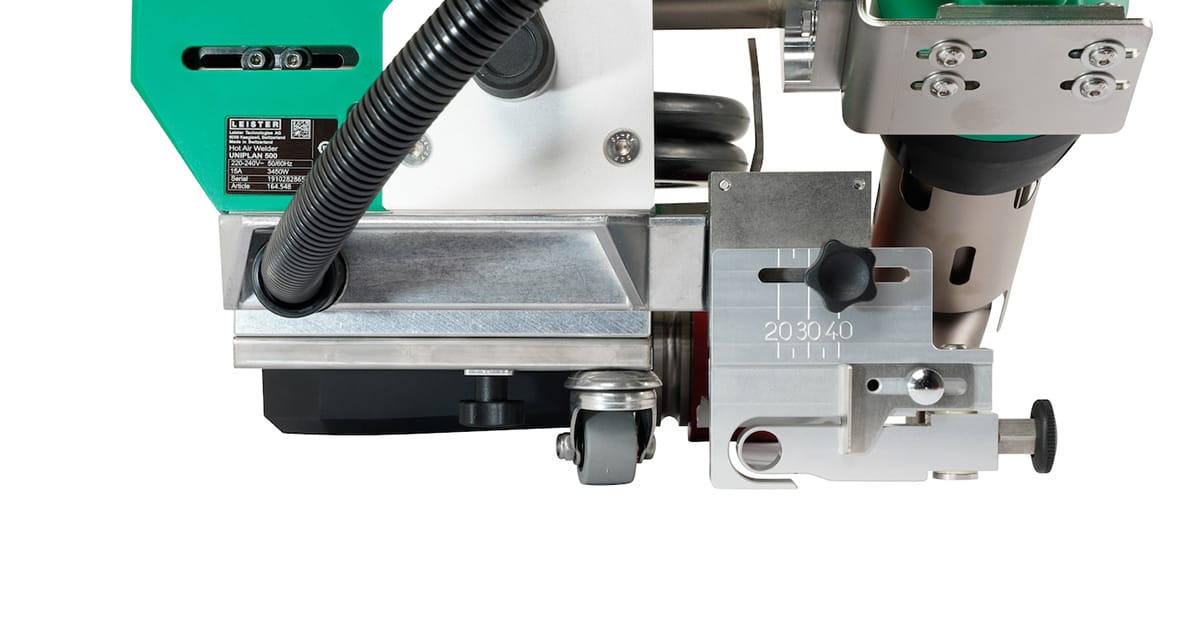

In the fast-paced world of construction and industrial applications, efficiency and reliability are paramount. Did you know that improper welding can lead to costly project delays and safety hazards? Enter the UNIPLAN 500 from Leister, a game-changer in the realm of tarpaulin welding. In this article, we’ll explore the top five advantages of the UNIPLAN 500, demonstrating how it simplifies the welding process for truck tarpaulins, advertising banners, and tents. By the end, you’ll understand why this innovative tool is essential for contractors and builders in Saudi Arabia.

So, what’s in it for you? Read on to discover how the UNIPLAN 500 can enhance your welding projects, save you time, and improve your overall productivity.

User-Friendly Operation

The UNIPLAN 500 is designed with the user in mind. One of its standout features is a device that lifts the material to be welded, eliminating the need for manual folding of tarpaulins before welding. This not only streamlines the process but also enhances safety. The semi-automatic nozzle swiveling system allows for controlled movements, significantly reducing the risk of burns for both experienced users and novices alike.

With the UNIPLAN 500, you can focus on the task at hand without the hassle of complicated setups. This ease of use makes it an ideal choice for contractors and builders in Riyadh and Jeddah, where efficiency is key to meeting project deadlines.

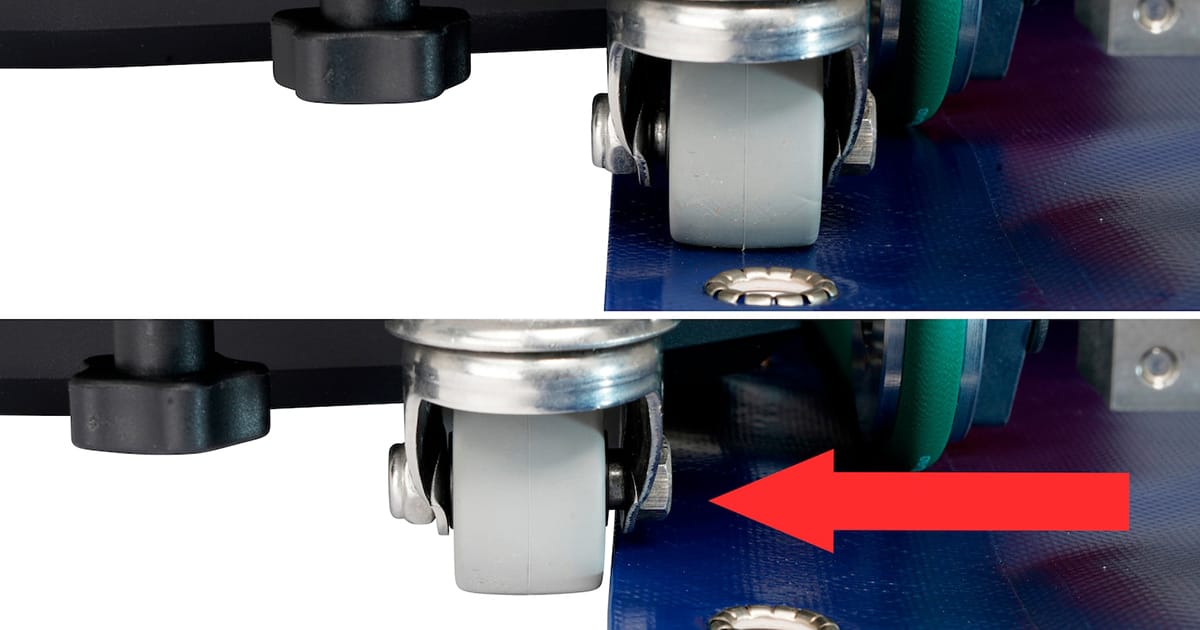

Navigate Obstacles with Ease

Welding tarpaulins often involves navigating around obstacles such as eyelets, rivets, or tensioning hooks. The UNIPLAN 500 addresses this challenge with its manually adjustable swivel castor wheel. If you encounter an obstacle, simply move the swivel castor wheel by hand to avoid it, ensuring a smooth welding process without interruptions.

This feature is particularly beneficial for construction professionals who frequently work with complex materials and need to maintain a high level of productivity. The UNIPLAN 500 allows you to adapt quickly to your working environment, making it a valuable asset on any job site.

Seamless Transition Between Welding Types

Flexibility is crucial in the construction industry, and the UNIPLAN 500 delivers just that. Users can effortlessly switch from overlap welding to hem or pipe welding in a single step, without the need for any tools. This seamless transition saves time and enhances workflow, allowing you to tackle various welding tasks with confidence.

Whether you’re working on a large-scale project or a smaller job, the ability to adapt quickly to different welding requirements makes the UNIPLAN 500 an indispensable tool for contractors and builders in Saudi Arabia.

Maintenance-Free Performance

One of the standout features of the UNIPLAN 500 is its maintenance-free Hot Air Blower – Air Heater. The brushless motor ensures that you can focus on your work without worrying about regular maintenance. With a powerful blower motor, the UNIPLAN 500 achieves a significantly higher welding performance compared to conventional automatic welding machines.

With a maximum speed of 16 meters per minute (52.5 ft/min), this welder not only enhances productivity but also ensures high-quality results. For construction professionals in Riyadh and Jeddah, this means less downtime and more efficient project completion.

Intuitive Display for Effortless Operation

The UNIPLAN 500 features an intuitively designed display that simplifies operation. Users can easily set and save material-specific parameters, ensuring consistent results across projects. This feature is particularly beneficial for contractors who need to maintain quality while working on multiple jobs.

By streamlining the setup process, the UNIPLAN 500 allows you to focus on what matters most—delivering exceptional results for your clients. This efficiency is crucial in the competitive construction market of Saudi Arabia, where every minute counts.

Value-Added Services from Global Source

At Global Source, we understand that investing in high-quality equipment like the UNIPLAN 500 is just the beginning. That’s why we offer a range of value-added services to support your welding needs. Our qualified specialists provide maintenance and repair services, ensuring your equipment remains in top condition. We use only original spare parts and conduct comprehensive safety checks and functionality tests after each service, guaranteeing performance on par with new devices.

Additionally, we offer customised training sessions tailored to your specific needs, either at our office in Riyadh or at your location. This ensures that you and your team are fully equipped to maximise the potential of your welding equipment.

Practical Tips for Successful Tarpaulin Welding

To make the most of your UNIPLAN 500 and ensure successful tarpaulin welding, consider the following practical tips:

- Prepare Your Materials: Ensure that the tarpaulins are clean and free from debris before starting the welding process. This will help achieve a strong bond and prevent any defects in the weld.

- Familiarise Yourself with the Equipment: Take the time to read the user manual and understand the features of the UNIPLAN 500. Familiarity with the machine will enhance your efficiency and safety.

- Practice on Scrap Material: If you’re new to the UNIPLAN 500, practice on scrap pieces of tarpaulin to get a feel for the machine’s operation and settings before tackling your main project.

- Adjust Settings for Different Materials: Different types of tarpaulin may require different welding temperatures and speeds. Use the intuitive display to adjust settings accordingly for optimal results.

- Regular Maintenance Checks: While the UNIPLAN 500 is maintenance-free, it’s still important to perform regular checks to ensure everything is functioning correctly. This will prolong the life of your equipment and maintain its performance.

By following these tips, you can enhance your welding skills and ensure that your projects are completed to the highest standards.

Final Thoughts on the UNIPLAN 500

The UNIPLAN 500 from Leister is more than just a welding machine; it’s a reliable partner for construction professionals in Saudi Arabia. With its user-friendly design, high performance, and maintenance-free operation, it stands out as a top choice for tarpaulin welding. Whether you’re working on truck tarpaulins, advertising banners, or tents, the UNIPLAN 500 simplifies the process and enhances your productivity.

As you consider your options for welding equipment, remember that investing in quality tools like the UNIPLAN 500 can significantly impact your project outcomes. With the support of Global Source, you can ensure that you have not only the best equipment but also the necessary training and maintenance to keep your operations running smoothly.

Ready to elevate your welding projects? Request a quote today, or call us for more information. You can also WhatsApp us to discuss your specific needs and how we can assist you in achieving your project goals.