Groover 500 LP

Revolutionize your flooring projects with the Groover 500 LP—a compact, cordless powerhouse built to handle diverse materials and environments with effortless precision.

- Cordless operation with dual batteries for uninterrupted productivity

- Universal milling blade compatible with PVC, PE, PUR, linoleum, and rubber

- Adjustable groove depth (0 to 0.24 inches) for consistent results on all surfaces

- Built-in LED light for enhanced visibility in low-light environments

- Three-point stand support ensures stability and precision during use

- Rotating dust tube allows grooving as close as 0.98 inches to walls or obstacles

- Brushless motor design for low maintenance and long-lasting performance

- Optional vacuum cleaner adapter for dust-free operation in hygiene-critical areas

Sunday - Thursady

08:00 AM - 06:00 PM

Disclaimer: Please note that images or illustrations may differ from the actual products due to presentation reasons and are therefore non-binding. Technical changes and errors are excepted. For the most accurate information, contact our customer service team.

Leister Groover 500 LP: The Ultimate Cordless Grooving Machine for Precision and Efficiency

For construction professionals in Riyadh and Jeddah, the Leister Groover 500 LP redefines precision and versatility in floor grooving. Imagine effortlessly creating clean, precise grooves for weld seams and joints on a variety of flooring materials—without the hassle of cords or cables. This cordless marvel is designed to meet the demands of modern construction projects while ensuring safety, efficiency, and reliability.

Key Features and Benefits

- Cordless Operation with Dual Batteries: Powered by two rechargeable batteries, the Groover 500 LP eliminates the need for power outlets and extension cables. With a charging time shorter than the operating duration, you can seamlessly switch between batteries, ensuring uninterrupted productivity on-site in Saudi Arabia.

- Universal Milling Blade: The general-purpose milling cutter is compatible with a wide range of resilient floor coverings, including PVC, PE, PUR, linoleum, and rubber. This versatility ensures that one machine can handle diverse materials, saving both time and costs for contractors in Riyadh and Jeddah.

- LED Illumination for Enhanced Visibility: The built-in LED light illuminates the grooving area, making it easier to work on dark-coloured floors or in low-light environments. This feature is especially valuable in industrial kitchens, hospitals, and clean rooms where precision is critical.

- Adjustable Groove Depth (0 to 0.24 inches): Equipped with a sensor roller, the Groover 500 LP maintains consistent groove depth on both even and uneven surfaces. This ensures professional-quality results, whether you’re working on small areas like kindergartens or large spaces like gymnasiums.

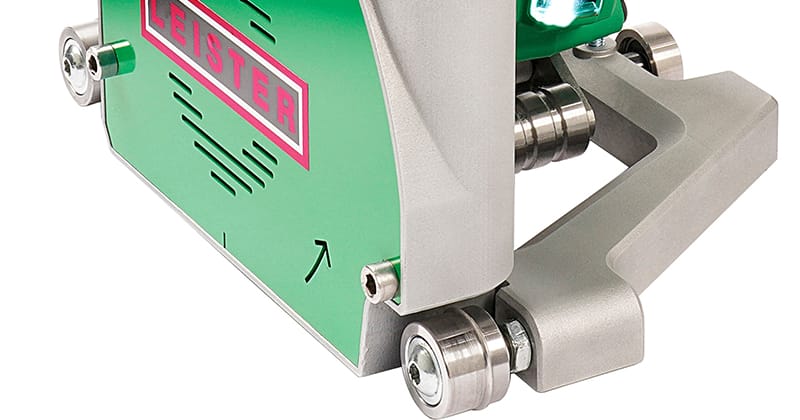

- Three-Point Stand Support for Stability: The guide, tracking, and running rollers provide exceptional stability during operation, minimizing vibrations and ensuring smooth, accurate grooves every time. This feature is particularly beneficial when working near walls or other obstacles.

- Side Stop for Precise Alignment: The practical side stop allows you to groove along rails or edges with ease, ensuring straight and uniform lines. This is ideal for installing hollow cone profiles and moulding baseboards in facilities with strict hygiene regulations.

- Rotating Dust Tube for Close Proximity Work: The rotating dust tube enables grooving as close as 0.98 inches to walls or objects, making it perfect for detailed work in tight spaces. Combined with an optional vacuum cleaner adapter, this feature ensures compliance with hygiene standards in hospitals and clean rooms across Saudi Arabia.

- Brushless Motor for Low Maintenance: Unlike traditional motors, the brushless design eliminates the need for carbon brush replacements, reducing downtime and maintenance costs. This makes the Groover 500 LP a reliable long-term investment for construction professionals.

- Simplified Blade Replacement Process: Changing the cutter blade is quick and safe, thanks to a locking mechanism that prevents accidental injuries. Uniform screws and an integrated socket wrench further streamline the process, enhancing user convenience.

Ideal Use Cases

The Leister Groover 500 LP excels in a variety of scenarios, making it indispensable for construction professionals in Saudi Arabia. Whether you’re laying resilient flooring in schools, hospitals, or industrial kitchens, this machine delivers unmatched precision and efficiency. Its ability to operate cordlessly makes it perfect for switching between rooms or working in remote areas without access to power outlets. Additionally, its compatibility with vacuum cleaners ensures compliance with stringent hygiene requirements, making it a top choice for projects in clean rooms and healthcare facilities in Riyadh and Jeddah.

For contractors, builders, and DIY enthusiasts seeking a reliable, high-performance tool, the Groover 500 LP stands out as a must-have addition to your toolkit. With its innovative design and robust functionality, it addresses the challenges of modern flooring projects while prioritizing safety and ease of use.

Support and Services for Groover 500 LP from Global Source

At Global Source, we are committed to providing professionals in Riyadh and Jeddah with the highest quality products and services. Our partnership with Leister ensures that you receive cutting-edge welding solutions backed by over 70 years of expertise. Additionally, we offer:

- Comprehensive maintenance and repair services for Groover 500 LP using original spare parts.

- Customized training sessions for Leister machines, available at our offices or your location.

- Local support and quick delivery options to keep your projects on track.

Get Your Groover 500 LP Today!

Don’t miss out on the opportunity to elevate your welding capabilities. Stock is moving fast at our Riyadh and Jeddah locations! Contact Global Source today to order your Groover 500 LP and experience the difference quality makes in your projects.

Sunday - Thursady

08:00 AM - 06:00 PM

Get personalized quote tailored to your needs on WhatsApp

Technical Data

-

Article167.451

-

Voltage Battery18 V

-

Battery Capacity90 Wh

-

Voltage230 V

-

Power90 W

-

Milling Blade TypeTungsten Carbide Parabolic – 12 Teeth

-

Milling Blade Diameter130 mm

-

Milling Depth0 – 6 mm

-

Joint Width3.5 mm

-

Brushless Drive MotorYes

-

Length445 mm

-

Width212 mm

-

Height336 mm

-

Weight5.5 kg

-

PlugEU/CH, 2 Poles, 2.5A

-

ApprovalsCB Certification; CE; UKCA

-

Country of OriginP.R. China

Highlights

Evenly Groove Without a Cable

Cordless joint milling for universal use

Cordless

The cordless GROOVER 500-LP grooving machines safely and reliably grooves joint depths up to 2.8 in. for resilient floors made of PVC-P, PE and linoleum.

Sensor roller for reliable milling on uneven floors

Reliable

The sensor roller allows reliable milling with consistent joint depth, even on uneven floors.

Safe, three-point stand support

Stability

The GROOVER 500-LP is always safe due to the three-point support consisting of three wheels.

Applications

Nearly Limitless

Leister: A Legacy of Innovation in Plastic Welding Technology

Leister, a Swiss company with a rich history dating back to 1949, has established itself as a global market leader in plastic welding and process heat technologies. Renowned for their commitment to innovation and quality, Leister’s products have become the benchmark for industries requiring durable and efficient solutions. From roofing and civil engineering to tunneling and plastic fabrication, Leister’s tools are integral to various applications that demand precision and reliability.

Leister’s product portfolio is extensive, featuring hot-air hand tools, extruders, welding machines, and a wide array of accessories. These products cater to both DIY enthusiasts and industrial professionals, ensuring that every need is met with the highest standards of performance. Additionally, Leister Technologies AG extends its reach through the WELDY brand and private labeling options, further solidifying its presence in the global market.

With over 70 years of expertise, Leister continues to push the boundaries of technology, offering solutions that incorporate hot air, laser, and infrared technologies. Their unwavering dedication to research and development enables them to provide tailored solutions for diverse industrial requirements. This commitment to innovation, coupled with a global network of over 80 distributors, ensures that Leister remains at the forefront of the plastic welding and process heat industries.

Global Source is proud to partner with Leister, carefully curating their top-tier products to meet the specific needs of construction professionals in Saudi Arabia. By selecting only the best from Leister’s range, Global Source ensures that clients have access to reliable, efficient, and innovative solutions that enhance their projects and operations.

Construction Insights and Innovations

Stay Informed, Stay Ahead

Discover a wealth of knowledge designed for construction professionals navigating the dynamic landscape of Saudi Arabia. Our blog features articles that delve into the latest trends, tips, and innovations, covering everything from best practices in pipe welding to the advantages of Leister plastic welding solutions. Gain valuable insights that empower contractors, engineers, and builders to enhance their skills and optimize their projects. Join a community of forward-thinking professionals and elevate your expertise with every read.

Mastering Tarpaulin Welding: Discover the UNIPLAN 500 from Leister

Explore the advantages of the UNIPLAN 500 for tarpaulin welding. Experience seamless operation and expert support from Global Source.

Unleashing Power and Precision: The WELDPLAST 600 from Leister

The WELDPLAST 600 offers powerful performance and user-friendly features for construction professionals. Elevate your welding projects today!

Transform Your Flooring Projects with the UNIFLOOR 500 from Leister

Maximize your flooring efficiency with the UNIFLOOR 500. Enjoy eco-friendly operation and easy transport for all your projects.

Achieve Seamless Perfection: The UNIDRIVE 505 Revolutionises Pool Membrane Welding

Upgrade your pool building process with the UNIDRIVE 505. Enjoy time savings and superior seam quality for every project.

Leister WELDPLAST 605: The Ultimate Hand Extruder

Learn how the WELDPLAST 605 revolutionizes plastic welding. Achieve superior results with precision and efficiency in demanding environments.

Unleashing the Power of Precision: The Leister COMET 700 Hot Wedge Welding Machine

Invest in the COMET 700 for high-quality welds and efficient operations. Perfect for landfills, ponds, and aquaculture projects.

Building the Future: CARDI and Global Source Unite for Construction Excellence in Saudi Arabia

Experience a new era in construction with Global Source and CARDI. Access top-tier power tools and services tailored for your needs.

10 Compelling Reasons to Choose SHOXX Diamond Tools for Your Construction Projects in Saudi Arabia

Learn 10 compelling reasons to choose SHOXX diamond tools. Experience superior performance and safety for all your construction needs.