VPWS 1200

The VPWS 1200 is a game-changing automatic butt fusion machine designed to deliver precision, efficiency, and reliability for large-diameter pipe welding projects in Saudi Arabia’s construction and industrial sectors.

- Wide welding range: Handles PE, PP, and PVDF pipes from 630mm to 1200mm in diameter.

- Precise temperature control: Removable PTFE-coated heating plate with electronic regulation up to 270°C.

- Effortless operation: Compact and ergonomic design ensures ease of use on-site.

- Advanced automation: Electrohydraulic control unit with pressure regulation (0-16 MPa) for consistent weld quality.

- Integrated crane hoist: Electric hoist simplifies handling of heavy components, enhancing safety and efficiency.

- Durable construction: Lightweight aluminium frame built for durability and portability.

- German engineering: Designed for precision and reliability in Germany and manufactured in PRC, backed by local support in Riyadh and Jeddah.

- Versatile applications: Ideal for water supply, gas pipelines, sewage systems, and industrial projects.

Sunday - Thursady

08:00 AM - 06:00 PM

Disclaimer: Please note that images or illustrations may differ from the actual products due to presentation reasons and are therefore non-binding. Technical changes and errors are excepted. For the most accurate information, contact our customer service team.

VPWS 1200: The Ultimate Solution for Reliable and Efficient Butt Welding of Large-Diameter Pipes

Looking for a robust, reliable, and versatile butt welding machine that simplifies the fusion process while delivering consistent results? The VPWS 1200 from Väli is your answer. Designed in Germany and manufactured with precision in PRC, this automatic butt fusion machine is engineered to handle PE, PP, and PVDF pipes ranging from 630mm to 1200mm in diameter, making it an indispensable tool for construction professionals in Riyadh, Jeddah, and across Saudi Arabia.

Key Features of the VPWS 1200

- Wide Welding Range: Capable of welding pipes with diameters of 630mm, 710mm, 800mm, 900mm, 1000mm, and 1200mm, the VPWS 1200 ensures versatility for large-scale projects such as water supply systems, gas distribution networks, and industrial pipelines.

- Compact and Ergonomic Design: Despite its heavy-duty capabilities, the VPWS 1200 boasts a compact design that simplifies transportation and operation on-site. Its aluminium frame ensures durability without adding unnecessary weight.

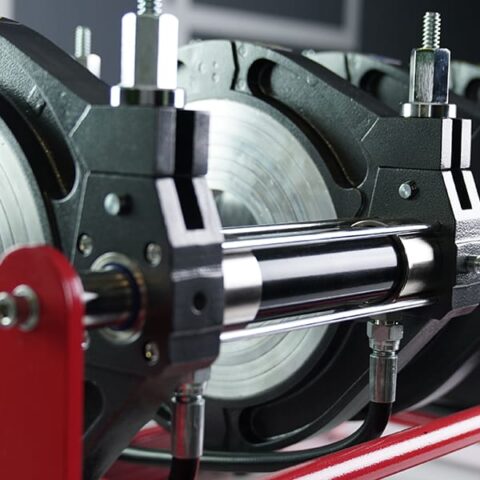

- Removable Electric Facing Tool: Equipped with a double cutting-edge blade system, the electric planning tool ensures precise and clean pipe ends, critical for achieving strong, leak-proof welds.

- PTFE-Coated Heating Plate: Featuring electronic temperature control, the removable heating plate maintains consistent surface temperatures up to 270°C with a deviation of less than ±10°C, ensuring optimal fusion conditions.

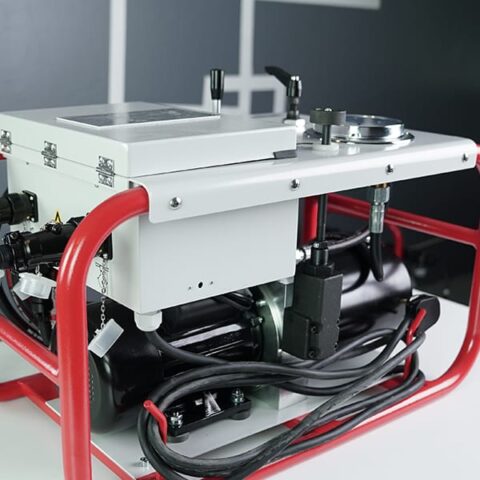

- Electrohydraulic Control Unit: This advanced system allows for seamless pressure regulation within the range of 0-16 MPa, guaranteeing high-quality welds even for small-diameter pipes thanks to low starting pressure settings.

- Integrated Crane Hoist: With a power rating of 1.1KW, the electric crane hoist facilitates safe and efficient handling of the facing tool and heating plate, reducing manual effort and enhancing safety.

- Electronic Timer and Temperature Controller: Simplify the welding process with an intuitive countdown timer and temperature display, enabling operators to monitor heating and cooling phases accurately.

- Multifunctional Applications: Suitable for sanitary installations, drain pipe systems, gas pipelines, and other fluid-carrying applications, the VPWS 1200 adapts effortlessly to diverse project requirements.

- High-Powered Components: Boasting a total power output of 29.5KW (heating plate: 21.5KW, planning tool: 4.0KW, hydraulic unit: 3.0KW), this machine delivers exceptional performance under demanding conditions.

- German Engineering, Local Support: Backed by German precision engineering and supported by Global Source’s Riyadh and Jeddah offices, the VPWS 1200 combines innovation with accessible maintenance and repair services.

Ideal Use Cases for the VPWS 1200

The VPWS 1200 excels in scenarios requiring durable and precise welding of large-diameter thermoplastic pipes. Whether you’re working on water supply infrastructure in Riyadh, gas distribution networks in Jeddah, or sewage and drainage systems across Saudi Arabia, this machine ensures reliable joints that meet global compliance standards like DVS and ISO. Additionally, its adaptability makes it perfect for industrial pressure pipelines, irrigation systems, and road construction projects where efficiency and quality are paramount.

Construction firms, precast manufacturers, and industrial clients will appreciate the VPWS 1200’s ability to streamline operations while maintaining superior welding quality. For DIY enthusiasts and trades people seeking professional-grade tools, this machine offers unmatched value through its combination of functionality, ease of use, and long-term reliability.

Choose the VPWS 1200 from Väli—a trusted partner for all your pipe welding needs in Saudi Arabia.

Sunday - Thursady

08:00 AM - 06:00 PM

Get personalized quote tailored to your needs on WhatsApp

Technical Data

-

ModelVPWS 1200

-

Pipe Welding Ranges630, 710, 800, 900, 1000, 1200

-

Working Voltage380V, 3P, 50/60 Hz

-

Heating Plate Max. Temp270°C

-

Deviation in Heating Plate Surface Temperature<±10°C

-

Pressure Adjustment Ranges0-16 Mpa

-

Heating Plate Power21.5KW

-

Planning Tool Power4.0KW

-

Hydraulic Unit Power3.0KW

-

Crane Power1.1KW

-

Total Power29.5KW

-

Weight2800KG

Accessories List

For Monitoring, Detecting, and Recording Welding Parameters

Stub End Gripping Equipment for Short Spigot Flanges

For Easy Moveability

Väli: Elevating Pipe Welding Standards in Saudi Arabia

Väli stands as a beacon of innovation in the realm of pipe welding solutions, offering a comprehensive range of products that cater to the diverse needs of the construction industry. With a focus on butt fusion, socket fusion, and electrofusion technologies, Väli ensures that every weld is not just a connection but a commitment to quality and durability. The brand’s tagline, “Welding. Together.”, encapsulates its dedication to unifying precision engineering with user-friendly designs, making it an ideal choice for contractors and engineers in Riyadh and Jeddah.

At the heart of Väli’s offerings is a versatile product line that accommodates all thermoplastic materials, including PE, PP, PVDF, and PB, across various pipe sizes from 20mm to 3130mm. This adaptability is complemented by advanced automation features such as CNC technology and real-time monitoring, ensuring that every welding task is executed with unmatched accuracy. Furthermore, Väli’s commitment to global compliance with DVS, ISO, and regional safety standards underscores its reliability as a trusted partner in critical infrastructure projects, from water supply systems to gas distribution networks.

Global Source proudly curates the best products from Väli, ensuring that construction professionals in Saudi Arabia have access to top-tier welding solutions. Our comprehensive services, including maintenance, repair, and customized training, align seamlessly with Väli’s mission to provide exceptional support and expertise. By choosing Global Source, you are not only investing in high-quality products but also in a partnership that prioritizes your success and the longevity of your projects.

Construction Insights and Innovations

Stay Informed, Stay Ahead

Discover a wealth of knowledge designed for construction professionals navigating the dynamic landscape of Saudi Arabia. Our blog features articles that delve into the latest trends, tips, and innovations, covering everything from best practices in pipe welding to the advantages of Leister plastic welding solutions. Gain valuable insights that empower contractors, engineers, and builders to enhance their skills and optimize their projects. Join a community of forward-thinking professionals and elevate your expertise with every read.

Unleashing the Power of Precision: The Leister COMET 700 Hot Wedge Welding Machine

Invest in the COMET 700 for high-quality welds and efficient operations. Perfect for landfills, ponds, and aquaculture projects.

Unleashing Power and Precision: The WELDPLAST 600 from Leister

The WELDPLAST 600 offers powerful performance and user-friendly features for construction professionals. Elevate your welding projects today!

10 Compelling Reasons to Choose SHOXX Diamond Tools for Your Construction Projects in Saudi Arabia

Learn 10 compelling reasons to choose SHOXX diamond tools. Experience superior performance and safety for all your construction needs.

Mastering Tarpaulin Welding: Discover the UNIPLAN 500 from Leister

Explore the advantages of the UNIPLAN 500 for tarpaulin welding. Experience seamless operation and expert support from Global Source.

Leister WELDPLAST 605: The Ultimate Hand Extruder

Learn how the WELDPLAST 605 revolutionizes plastic welding. Achieve superior results with precision and efficiency in demanding environments.

Achieve Seamless Perfection: The UNIDRIVE 505 Revolutionises Pool Membrane Welding

Upgrade your pool building process with the UNIDRIVE 505. Enjoy time savings and superior seam quality for every project.

Unlocking Efficiency: The TRIAC AT Hot Air Hand Tool for Plastic Welding Professionals

Transform your construction projects with the TRIAC AT. Experience durability, safety, and energy efficiency with Global Source.

Understanding the Impact of New ASTM Standards on Geomembrane Welding in Saudi Arabia

Meet the latest ASTM standards in geomembrane welding with Leister equipment. Ensure quality and compliance with Global Source.